Understanding responsible battery supply chains

Do we really understand how to measure responsible sourcing in EV and battery supply chains?

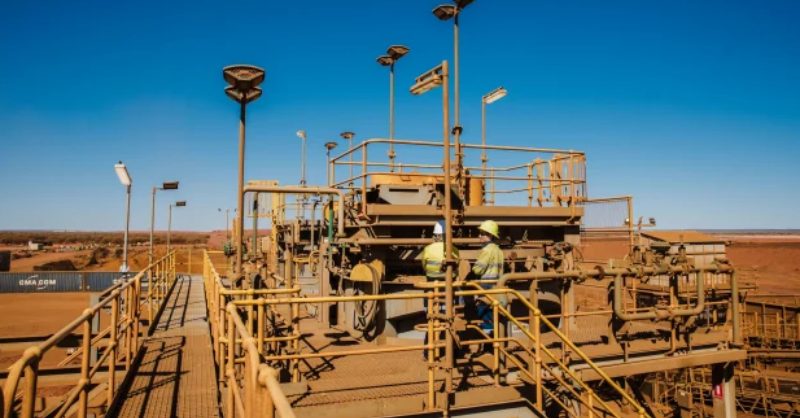

Do we really understand how to measure responsible sourcing in EV and battery supply chains? As the demand for EV's and stationary energy storage grows, we are going to need more batteries. This is understandably leading to attention being paid to where the required raw materials will come from (do we have enough supply, at the right price, and from where).

And it's also leading to questions about how these raw materials are mined and processed. What you could broadly call responsible sourcing.

Part of how this will happen is related to regulation from government, and policy action (including audits) by companies. But this is unlikely to be enough. To quote Julie Schindall from Levin Sources "of all the practices we’ve seen work, especially deep into the supply chain, engagement is the “make or break” factor".

Let's dig into this a bit more.

Starting at the beginning. A recent report from Rainforest Foundation Norway (RFN) and AidEnvironment found (to quote):

"a disturbing lack of commitments on deforestation in mineral supply chains across EV battery producers and automakers alike and identified ‘broken links’ between automakers' and battery manufacturers' policies."

What they mean by 'broken links' is that even where the automaker has a deforestation commitment, in some cases they source raw materials from battery manufacturers who have no similar commitment. Which raises the question of how real the deforestation commitment is in practice.

In the interests of balance, they highlight that some EV automakers are doing better in this regard than others - specifically calling out Tesla, BMW and Mercedes Benz as being among the best performers.

As an aside, this is broadly consistent with a recent PIRC report (Leading the Charge 2024). This found that there had been steady progress across the industry, in particular on fossil-free steel and human rights due diligence. US automakers are making the fastest progress, led by Tesla who shot up in the rankings from #9 to #3 in one year. However, progress by the industry as a whole is lackluster when compared to the scale of the challenge ahead.

This got me thinking. I don't know about you, but responsible sourcing is one of those topics that I feel I don't know enough about. I understand what it means. And as an investor I understand why its important.

What I am less sure about is the key question ...'how do we know that it's actually happening on the ground'.

As we highlighted at the beginning of the blog, one part of the answer is regulation. For instance in Europe we now have the EU Batteries Regulation.

To quote, this 'mandates companies to establish a batteries due diligence policy, for the purpose of addressing and mitigating human rights, environmental and climate change impacts along the battery materials value chain.'

If you want to know more about how this regulation will work, I recommend a recent Insight blog from Levin Sources (The new EU Batteries regulation: driving companies to higher due diligence standards).

Another element will be sustainable sourcing policies and practices from companies. For instance, as the PIRC report highlights, Ford has a standalone responsible minerals sourcing policy, which goes beyond conflict minerals to cover cobalt, mica, lithium and nickel.

But, regulation, policies and audit's, on their own, are unlikely to be enough.

This brings us back to engagement. Many companies will respond to this by saying, we cannot have a conversation with thousands of suppliers. And this is true. On their own they cannot.

Which is where the power of collaboration comes in. To again quote Julie Schindall "collaborations, partnerships, industry initiatives, multistakeholder initiatives, dialogue platforms: over and over we have seen their power in engaging, supporting and pushing supply chain partners to rise to the standard that we expect of all companies to do business with respect for people and planet."

So as well as regulation and policy, let's also focus on collaboration. This is a topic I want to come back to - after I have done a bit more research. So watch this space for real world examples.

I want to finish this part of the blog with 'why is responsible sourcing important'?

One obvious answer is that it's the 'right thing to do'. Increasingly employees are 'voting with their feet', choosing not to work for companies that have poor social and environmental track records. This is recognised as a material issue for the mining industry - what a recent McKinsey article called the deterioration of the industries employee value proposition (I think that means less people what to work for them!).

And pressure is coming from customers to show that the product is being manufactured responsibly, from raw materials mining all the way through to the production process.

But there are also very direct financial implications for companies and investors. As Julie Schindall (from Levin Sources) said in a presentation back in May 2022 "companies ignore the perspectives of local communities at their peril - we see direct ties between harms to communities and material risks to mining companies".

We talked about this back in March last year in a blog titled 'Critical mineral mining meets social license'. In it we made the point that recent research from a Finnish team suggested that “social aspects are now considered the biggest risk facing the mining industry”. They particularly highlighted political risk, where mining plans come into conflict with environmental objectives and legislation.

Social license in mining is becoming increasingly important. And the answer is not to limit peoples opportunities to object.

Link to blog 👇🏾

Critical mineral mining meets social license

This article featured in What Caught Our Eye, a weekly email featuring stories we found particularly interesting during the week and why. Members get What Caught our Eye delivered direct to their email inbox once a week.

Click this link to register 👉🏾 https://www.thesustainableinvestor.org.uk/register/

Please read: important legal stuff.