Decarbonising shipping with the energy you don't use

Shipping is a big emitter of harmful gases. Regulation and innovation in fuels is an important path to reducing that. Increasing efficiency is also a big help and has a cost advantage too.

Summary: The cheapest and greenest energy is the one we don't use. In the built environment, improvements in energy efficiency such as insulation are key to decarbonising the sector. Shipping has its own 'insulation' or ways in which, even if the type of fuel remained the same, the amount consumed can be reduced. We introduce four main categories of energy efficiency for shipping: fuel consumption, onboard energy efficiency, voyage optimisation and port optimisation.

Why this is important: Alternative fuels are still not at a scale that can support current shipping behaviour globally. We need to find other ways to reduce emissions in conjunction. It just so happens that they can also reduce costs.

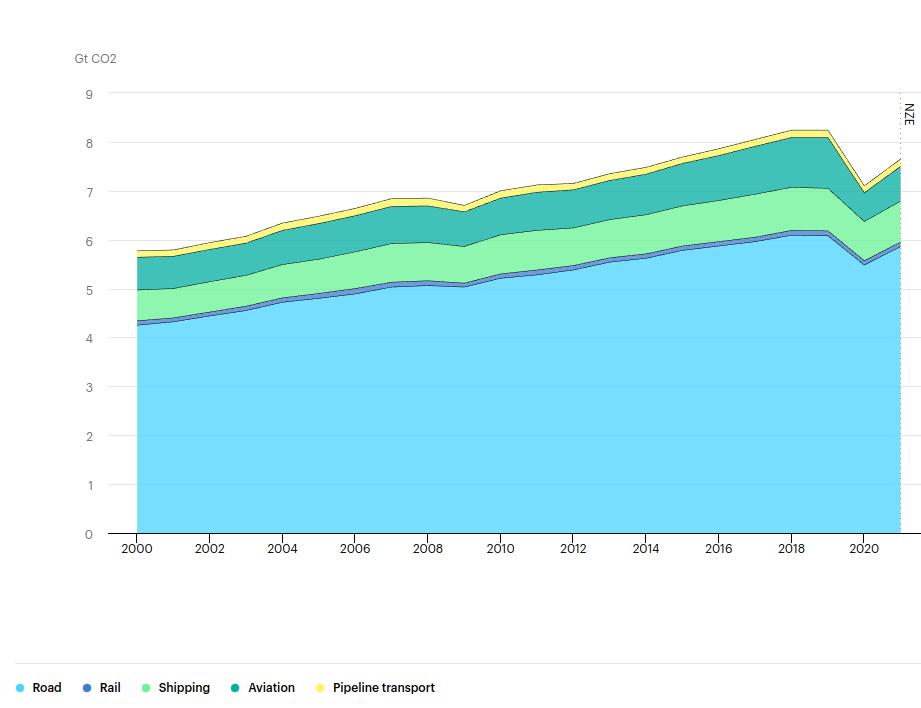

The big theme: Transportation has the highest reliance on fossil fuels of any sector. Approximately 91% of its energy comes from them. For 45% of countries, transport is the largest source of energy related emissions and it is the second largest source for the rest. Changing how we transport ourselves and our goods helps with both climate change and with health and well-being issues and is a rich vein for investment.

The details

Why do we care about shipping?

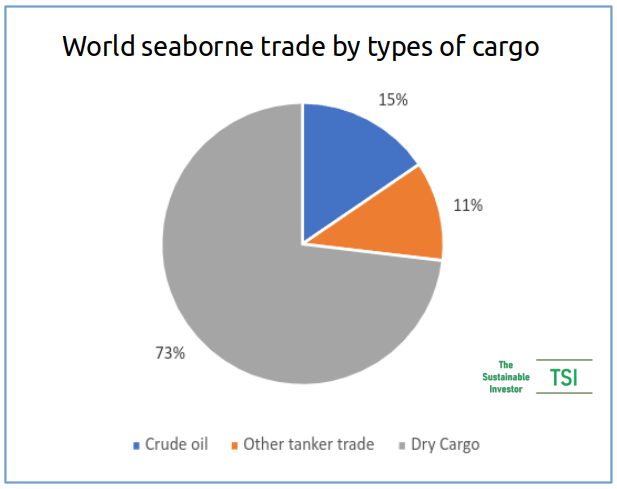

More than 80% of traded goods by volume are transported on ships. One of the largest cargoes is petroleum goods and its byproducts.

Energy products in total were approximately 36% of global seaborne trade in 2021 with almost two-thirds of oil produced globally moved by ship.

International shipping accounts for almost 3% of global energy-related CO2 emissions and is the second biggest transport emitter after road transportation, albeit that road transportation has almost seven times the emissions!

However, that doesn't tell the full story.

There are a number of different types of ships used for international trade. They can be BIG. The largest container ship in the world, for example, the MSC Irina, is the length of more than 3.5 football pitches and can carry 24,346 containers or almost 940,000 m3.

These big ships will use a lot of fuel. The most common type of fuel used by ships is Heavy Fuel Oil (HFO). It is commonly used in cargo ships as it is low cost, but it is also the most polluting. It has high concentrations of sulphur at 3.5%. Global shipping has historically been a material contributor to global anthropogenic (man-made) sulphur dioxide (SO2) emissions which is highly acidic when mixed with water causing, amongst other things, acid rain. Nitrogen Oxides (NOx) are also a byproduct of shipping (and indeed most forms of combustion in our atmosphere) which can cause a wide number of health issues.

In 2014 international shipping was estimated to contribute 16% of total anthropogenic SO2 emissions. In January 2015, air quality regulations from the International Maritime Organisation (IMO) came into force. These regulations were aimed at reducing the maximum allowed sulphur emissions by a factor of 10 in emission control areas (for example, the English Channel) from 1% (the limit since 2010) to 0.1% of fuel by mass. From January 2020, a further target for open ocean emissions of SO2 was set by the IMO reducing the limit from the pre-2020 level of 3.5% to 0.5%.

There have been a number of innovations in fuel type including low sulphur fuels with less than 0.5% ('Very Low Sulphur Fuel Oil') and 0.1% ('Ultra Low Sulphur Fuel Oil') sulphur content respectively, Liquid Natural Gas (LNG) and biofuels amongst others.

The majority of ships trading worldwide switched from using heavy fuel oil (HFO) to using VLSFO. The IMO reports an "extremely smooth" transition. However, there is some evidence to suggest that shipowners remain uncertain about how future technology, particularly the type of fuel, will develop, including availability at scale. Average ship age has been increasing. For example, container ship average age in 2011 was close to 10 years; in 2022 it was 13.7 years. Shipbuilding volumes more broadly remain below 2014 - 2017 levels.

In a future blog, we shall be covering these fuel innovations in more detail looking at how the energy that is used in shipping can be less polluting.

However, in this 'Perspective' we shall discuss the energy we don't use - it is after all the greenest and cheapest!

There is a broader consumption discussion. Do we need to consume as much as we do? Do we need to consume goods not produced in our locality? Given the potential transition from using fossil fuels for power generation and transport to electrification, the amount of shipping required to transport liquid or solid fuels is likely to reduce (although unlikely to disappear).

Even if we didn't change the type of fuel used, can we make the shipping industry more efficient, reducing how much energy is consumed and ultimately reduce emissions?

Let's take a look at that aspect in more detail.

The 'insulation' of shipping

As a former engineering student, it would be remiss of me to not mention some physics, chemistry or maths at this point, so I’ll restate the law of conservation of energy as follows:

Generation = Consumption

or in other words the energy generated upstream is consumed downstream in the built environment. If we can lower consumption, then we can lower generation which in turn should lower harmful emissions (even before we talk about the mode of power generation).

Furthermore, we can subdivide Consumption:

Consumption = Usage + Wastage

or in other words what we use usefully and what is lost to the universe (or used up un-usefully). Usage and Wastage can both be lowered through improvements in efficiency which can be both active and passive, and through behavioural changes.

We have talked about this a lot with regards the build environment. Here are some examples you can review:

There are parallels with shipping. If the bulk of harmful emissions from shipping come from how they are propelled, then if we can use less energy to propel them, all else being equal, then we should in turn reduce emissions. That means being more efficient.

The Global Marine Energy Efficiency Partnerships Project ('GloMEEP') was developed jointly by the UN Development Programme (UNDP) and the IMO, funded by the Global Environment Facility (GEF) and launched in September 2015. Its aim was to support the uptake and implementation of energy efficiency measures for shipping to ultimately reduce harmful emissions.

What are the different ways in which efficiency can be improved? I like to think of it in terms of four broad categories.

- Fuel consumption

- Onboard energy efficiency

- Voyage optimisation

- Port optimisation

Let's look briefly at what is possible in each of these energy efficiency categories.

Fuel consumption

If a ship can get from point A to point B using less fuel, regardless of what that fuel is, then there will be lower emissions. There are a number of ways to achieve that.

Slow steaming:

Large vessels like container ships typically travel at 20 - 24 knots. By sailing at slower speeds of 12 - 19 knots, ships can significantly reduce fuel consumption and greenhouse gas emissions. This is because of drag or the force imparted by a fluid (water and air) on the ship which increases as it goes faster. In fact the relationship is such that travelling twice as fast requires four times as much energy and hence fuel for the same distance.

The Marine Environmental Protection Committee (MPEC) of the IMO adopted an initial strategy on the reduction of GHG emissions from ships in April 2018 and the concept of slow steaming is specifically mentioned in Section 4.7(4):

"the use of speed optimization and speed reduction as a measure, taking into account safety issues, distance travelled, distortion of the market or trade and that such measure does not impact on shipping's capability to serve remote geographic areas"

From a cost perspective there are a number of considerations. Whilst fuel consumption will be lower as a whole, as the ship will be at sea for longer, the daily operational and travel costs will be higher. A 2019 study concluded that speed reductions of up to 30% will lead to net cost savings for the shipping industry in the majority of cases. It found that even in the case where fuel prices are very low or ships slow down beyond 30%, then the negative cost impacts are likely insignificant.

For a container ship normally using 200 tons of fuel over the course of a normal day at 24 knots, slow steaming at 21 knots a day would bring that fuel consumption down to around 125 tons for the day. A key engineering issue to bear in mind with slow steaming is the potential for increased carbon deposits in the turbochargers, particularly if operating beyond their designed for range.

Perhaps an obvious point with slow steaming is that it takes stuff longer to get where it needs to get to. That has implications for order and delivery times for goods. Consider purchasing goods from a retailer that is manufacturing and fulfilling orders in a country on the other side of the world. Slow steaming could mean that the delivery times are too long. However, if the retailer were fulfilling in your own country with a local warehousing and distribution network then that delivery time from customer order to receipt by the customer would be short, even if the goods were manufactured on the other side of the world , through good inventory management. In other words, slow steaming would not adversely impact the end consumer.

Improved hull design:

We mentioned that drag increases significantly with speed. Optimising the hull design of ships can reduce drag and improve hydrodynamic efficiency. This includes designing streamlined shapes, reducing appendages, and applying special coatings to decrease frictional resistance.

Although strictly part of the hull, another innovation is using wind propulsion, with optimised hulls and route optimisation to find the best wind to reduce fuel consumption.

Propulsion optimisation:

Upgrading propulsion systems can enhance energy efficiency. Measures such as using energy-saving propellers and installing variable speed drives, and adopting advanced engine technologies like waste heat recovery systems (discussed below) can significantly reduce fuel consumption.

The Wartsila EnergoProFin, for example, recovers energy from the rotating flow behind the propeller blades and claims to provide average fuel savings of 2% and a one year payback.

Trim optimisation:

A well balanced ship moving through the water does so with less resistance - think about when you go swimming. Properly managing cargo load, ballast water (used to stabilise the ship), and fuel distribution can optimise the ship's trim or how it sits in the water and reduce resistance and ultimately helps improve fuel efficiency. If you want to learn more about trim, check out this video:

Onboard Energy efficiency

There are a number of systems on a ship beyond the propulsion systems that need energy. Reducing the incremental energy required to power those systems ultimately saves fuel too.

Waste heat recovery:

Capturing waste heat generated by engines and using it to produce electricity or for other onboard applications can improve overall energy efficiency. Waste heat recovery systems can use this otherwise wasted energy, reducing the need for auxiliary power generation.

LED lighting and energy-efficient equipment:

Electrically powered equipment onboard ranges from lighting to navigation equipment to motors, pumps and refrigeration systems. Swapping those out with more energy efficient equivalents brings energy savings. For example, replacing traditional lighting systems with energy-efficient LED lighting.

Waste management and recycling:

We mentioned trim earlier, but also overall weight can impact fuel consumption too. Proper waste management practices, including recycling can help reduce unnecessary weight onboard.

Voyage optimisation

The Global Maritime Forum estimate that there are roughly 10% of latent performance improvements that could come from voyage optimisation. What do we mean by that?

If a ship travels a shorter distance it will use less fuel, all else being equal. Route optimisation is about minimising distance travelled. That can also mean dynamic adjustments to route should the unexpected happen such as adverse weather. There are plenty of software providers offering route optimisation solutions for ships.

Another area for optimisation is capacity utilisation or how much of the ship is being used to carry stuff. In theory, the higher the capacity utilisation or the fuller the ships are on every leg of the trips, then the fewer overall trips are required and the lower the energy consumption.

One issue is the trade imbalance over the past couple of decades with China being the manufacturing hub for many western consumed goods. For example, for the first 10 months of 2021, 59% of containers leaving US ports empty! That asymmetrical demand means that the Asia-to-US route freight rates are much higher than the US-to-Asia route.

As we discussed earlier with slow steaming, a rethink on which goods and services truly need to be globally sourced and what can be sourced locally could have an impact on the number of trips required.

Port optimisation

The port is where the ship offloads its cargo, takes on new cargo and replenishes its fuel and crew. It can also be a stopping off point for maintenance. There are measures that can reduce the burden on the ships's fuel sources and effectively reducing consumption.

Minimising the time that the ship is idle by having optimised loading and unloading procedures and providing onshore power connections, also known as shore power or cold ironing, allows ships to turn off their engines while docked and use electricity from the onshore grid.

Data and nudging

Many of the above innovations require reliable and timely data to make the required adjustments. There is an insightful report by the Global Maritime Forum on the role of data in maximising operational efficiency in shipping that is worth a read if you want to dive into the topic further.

Signol, which is a UK-based software company has developed a solution that uses behavioural science best practices and big data to 'nudge' captains to operate their vessels more efficiently, reducing fuel consumption, operating costs and emissions. They also work with the aviation industry and had previously saved Virgin Atlantic more than $6 million in fuel costs in just eight months. They also saved 24,000 tonnes of CO2.

Conclusion

Shipping is an important transportation mode but is also a material polluter emitting both greenhouse gases and other pollutants including SO2. Innovation and regulation on fuels is going to be a major way in which the shipping industry decarbonises. However, the cheapest and greenest energy is the one we don't use. In the built environment, improvements in energy efficiency such as insulation are key to decarbonising the sector. Through improvements in fuel consumption, voyage optimisation, onboard energy efficiency and port optimisation, even if the type of fuel remained the same, the amount of energy consumed can be reduced and in turn reduce emissions.

Something a little more bespoke?

Get in touch if there is a particular topic you would like us to write on. Just for you.

Contact us

Please read: important legal stuff.